Business

About Us

Solus Advanced Materials has the only battery foil plant in Europe and the first in North America

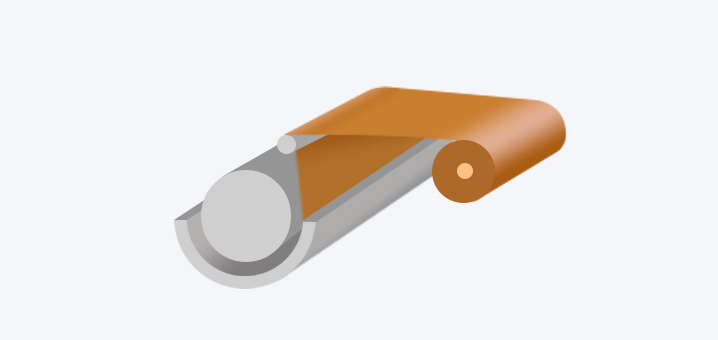

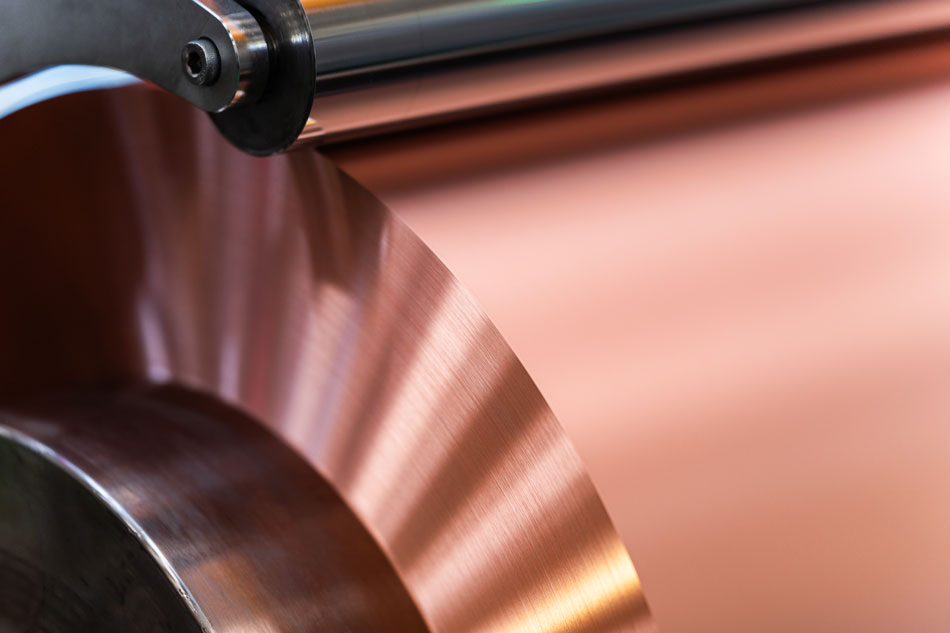

Battery foil is a material used in electric vehicle batteries, and is a key material in increasing total vehicle mileage and densifying batteries.

Solus Advanced Materials' battery foil plant in Hungary is the only battery foil production center in Europe, enabling us to ensure the fastest delivery of high-quality foils to local customers.

In Quebec (Canada), we are building North America's first battery foil plant, which will enable us to meet the growing North American demand in a timely manner.

Business information

Solus Advanced Materials has developed high-end, high-efficiency battery foils that can improve the total mileage of electric vehicles and enable battery densification, in our pursuit of continuous quality innovation.

In 1996, we developed the world's first battery foil. With more than 65 years of experience and know-how in copper foil manufacturing, we are able to guarantee stable production and supply.

Our high-quality battery foils are available for fast delivery to a wide range of global top-tier battery manufacturers.

Solus Advanced Materials' high-end battery foils are thin, yet have high strength and high elongation characteristics, contributing to lighter and higher-capacity batteries.

Strength

The world’s best high-end battery copper foil manufacturing technology

Lowest thickness

4.5㎛

Highest strength

70 kgf/㎟

Highest elongation

15%

- Developed and mass-produced Battery copper foil for the first time in the world

-

- Developed the world's first Battery copper foil in 1996

- Secured stable manufacturing and technology based on more than 65 years of cumulative experience and know-how in copper foil manufacturing

- Operating the only battery copper foil manufacturing base in Europe

-

- Competitive delivery time for clients in Europe, close technical support for customers

- Stable copper foil supply and quality compared to competitors

- Holding the world’s leading thin foil manufacturing technology

-

- We can customize battery packs to meet your specific needs

- We are contributing to lighter and higher capacity batteries.

Main Product

-

- Standard battery copper foil (BF-PLSP)

-

- Standard battery copper foil for electric vehicle batteries

- Thickness: 4.5~8μm

-

- High-elongation battery copper foil (SR-PLSP)

-

- Contributing to yield improvement by upgrading processability within the battery production process with high strength properties before heat treatment and increasing the life and stability of cylindrical and square batteries with high elongation properties after heat treatment

- Thickness: 5~8μm

-

- High-strength battery foil (HTS-PLSP)

-

- Possible to load much more active materials with high strength properties, contributing to the minimization of deformation at the time of battery charge and discharge by maintaining strength after heat treatment

- Thickness: 5~6μm

-

- Medium-strength battery copper foil (MTS-PLSP)

-

- A medium-strength battery copper foil with a strength of 40 to 50 kgf/mm² at room temperature. It is ideal for maintaining stability during the battery manufacturing process, and the performance of high-capacity batteries.

- Thickness: 5~8μm

-

- High-elongation battery copper foil (HE-PLSP)

-

- A high-elongation battery copper foil with an elongation of more than 13% after heat treatment. It is ideal for maintaining the performance of cylindrical batteries by effectively responding to the deformation that occurs during the process of charging and discharging.

- Thickness: 6~12μm

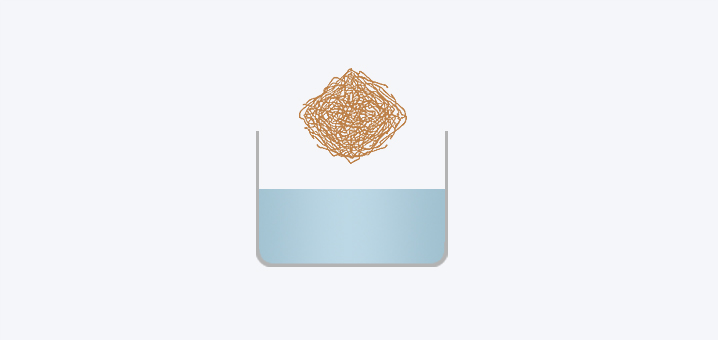

Manufacturing process

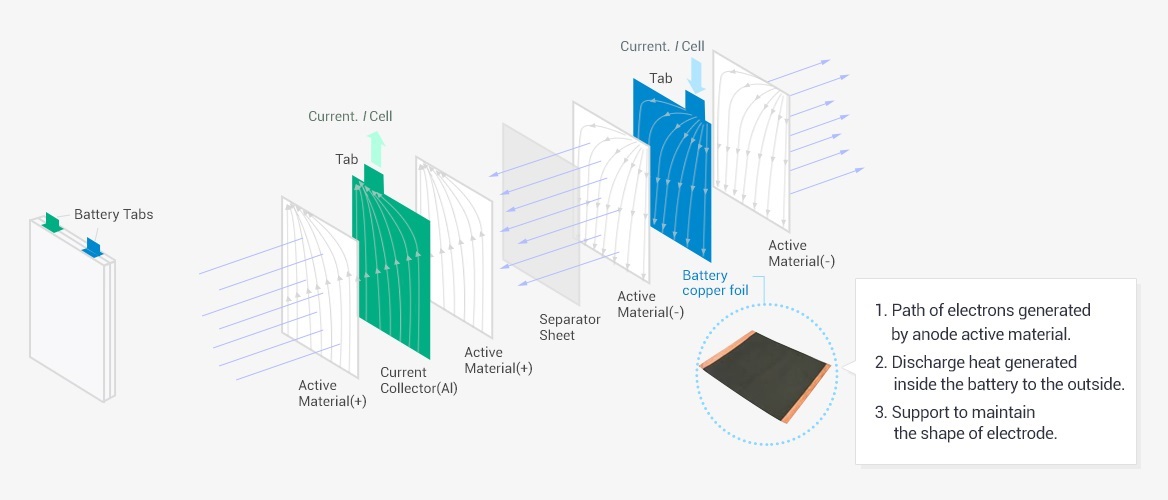

Product structure & role

- 1. Path of electrons generated by anode active material

- 2. Discharge heat generated inside the battery to the outside

- 3. Support to maintain the shape of electrode

Contact information

Quality Policy

Download- Vevőink elégedettségének növelése

- Környezeti lábnyomunk csökkentése

- Folyamatos minőségfejlesztés

- Dolgozóink elégedettségének és motivációjának növelése

- Minőségirányítási rendszerünk folyamatos fejlesztése

Ezen célok eléréséért közösen kell dolgoznunk!

- Increasing the satisfaction of our customers

- Reducing our environmental load

- Continuous quality improvement

- Increasing the satisfaction and motivation of our employees

- Continuous improvement of our quality management system